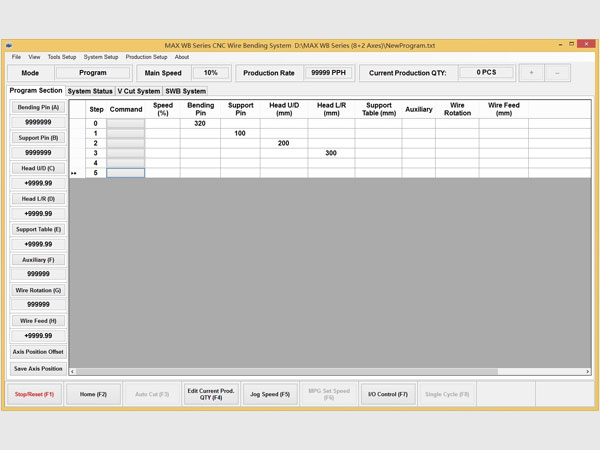

WB 100-8A

For decades, machines of the WB range have been world-widely used for long wire-forms 3D bending.

All fitted with an automatic centralized lubrication, their tables can be set either horizontally or with inclination.

A displacement of the bending head from left to right, perpendicularly to the wire line, extends the range of shapes directly produced, thus avoiding secondary operations.

WB 100-8A can be fitted with one-end or a double-end chamfering.

The feeding rate of the cutting tools is controlled by servomotor.

Technical characteristics

| Wire diameters (mm) | 3,0 – 10,0 (soft wire) 3,0 – 6,0 (hard wire) |

| Axes | 8 |

| Maximum wire feed speed | 71 m/mn |

| Distance “bending head – machine body” | 1010 mm |

| Dimensions | 4,80 x 1,60 x 1,95 m |

| Weight | 4 300 kg |