CNC Feeding systems

4/6-roller motorized wire and strip CNC feeding systems

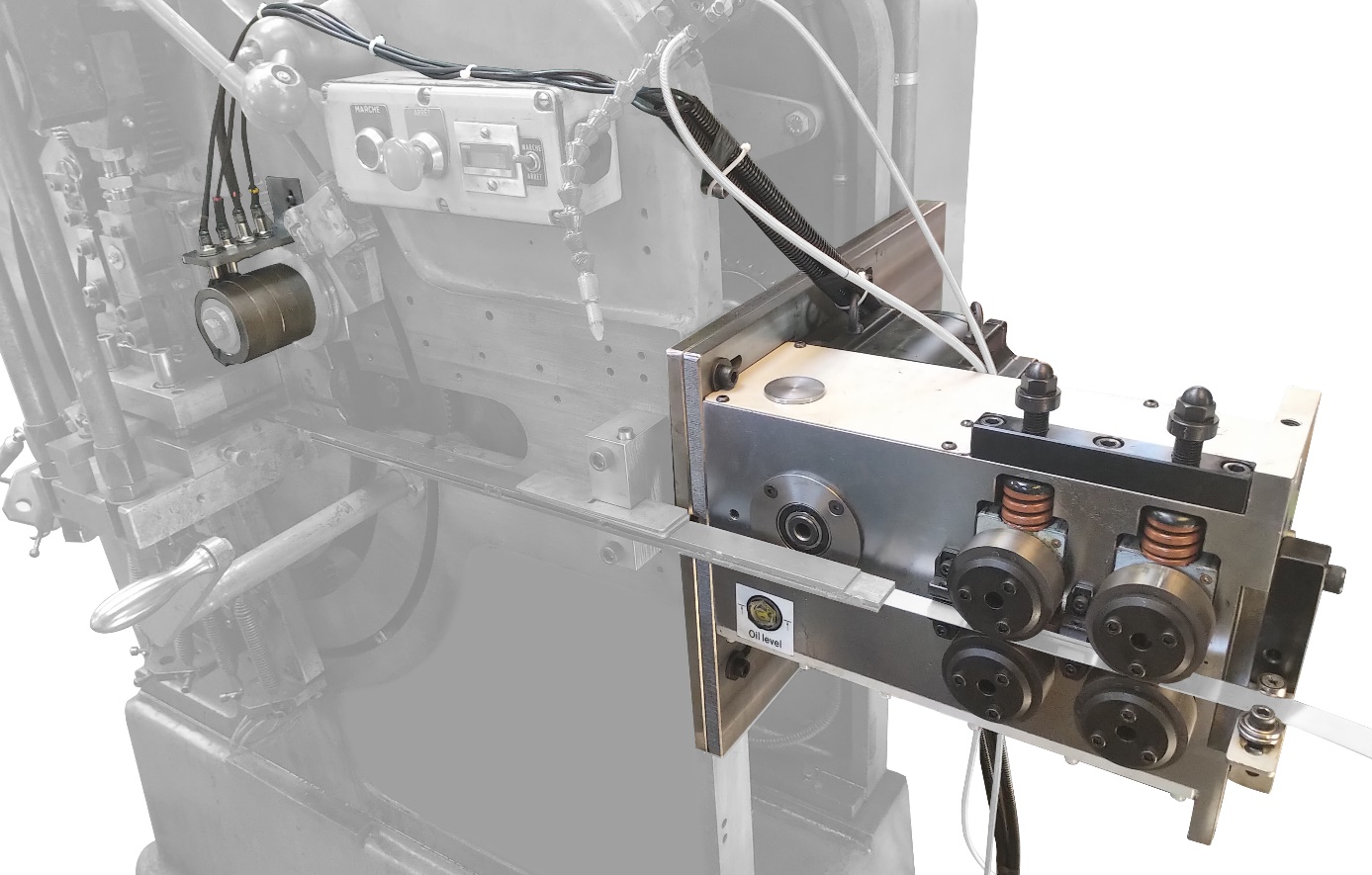

These systems are meant to be integrated onto an existing wire or strip working machine. They are delivered with a double-plane wire straightener. They have the ability to feed in two directions, 4 different lengths of material.

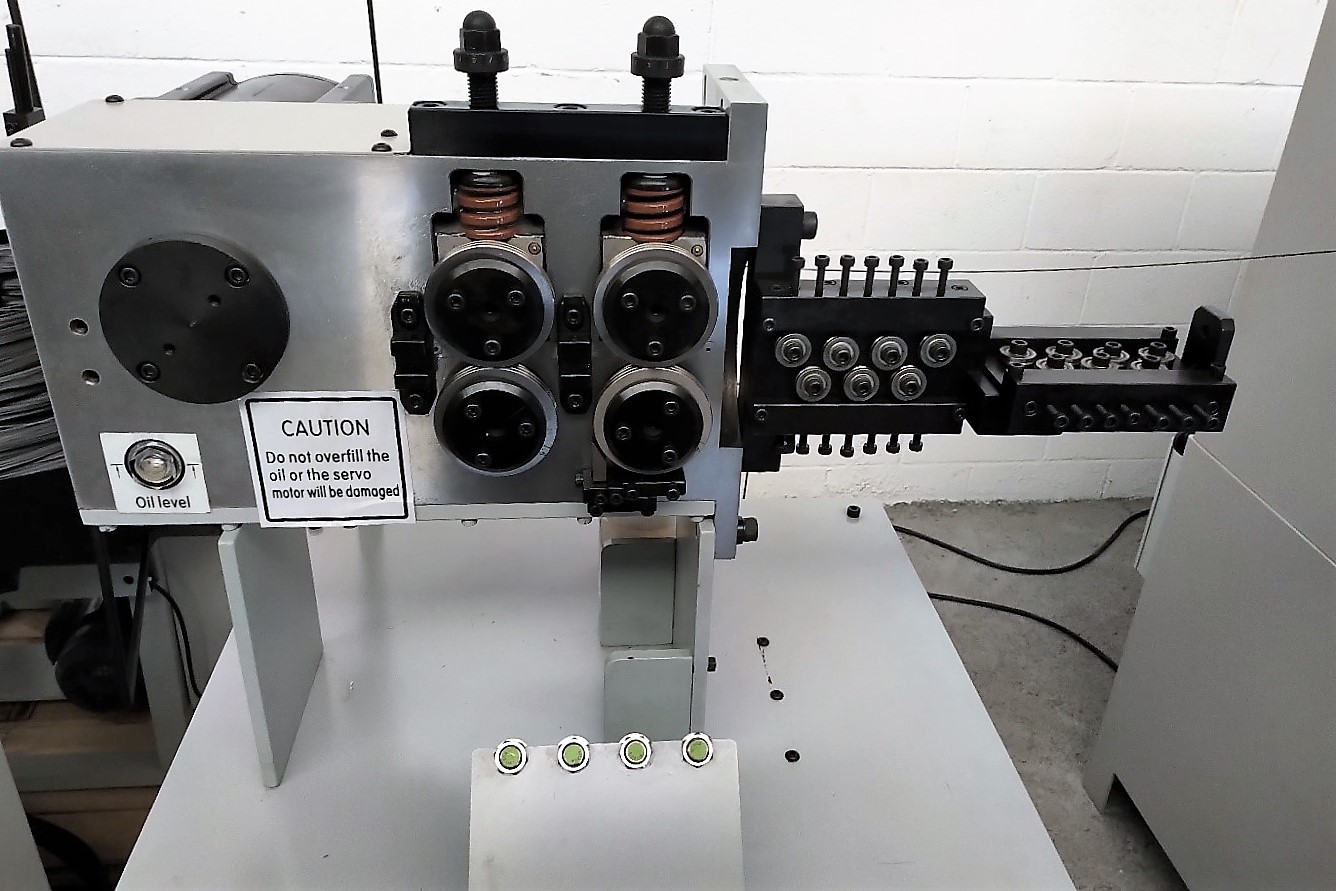

The systems house a PLC + colour touch screen to set-up feeding parameters: length and feeding speed. They feature a push-button to test each setting.

Two additional push buttons, on the main console, do help the setter to feed at manual speed in both directions. This speed can be adjusted as well.

Machine is equipped with 4 sensors. Each one will, independently, master one feeding, in speed, length and direction. It is the duty of the user to place each sensor in front of a metallic moving part in the main machine, in order to give the ‘top’ for each feeding (usually mounted on a cycle camshaft of the main machine.

The electronic parts + touch screen are mounted on a separate console, which console is movable on casters.

Standard languages: English and French.

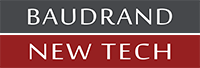

► Example of the system mounted on an Herckelbout MS 30 machine.

Technical characteristics

| Capacity | 0,2 – 2,5 mm (spring steel) 0.5 – 4,5 mm (600 n/mm²) |

| Rated power | 2,7 kW |

| Dimensions | 0,67 x 0,34 x 0,23 (h) |

| Max. wire feed speed | 121 m/mn |

| Accuracy | +/- 0.1 mm |

| Power | 220/380 V* – 50 Hz – 3 ph |

| Weight | 30 kg |

| Console dimensions / weight | 0,65×0,40×1,03 m / 25 kg |

*According to customer’s choice

Note : a 6-roller feeding system is available, for wires up to 3.5 mm spring steel, or 6 mm (mild steel).