Welding Machines for Mesh and Panels

SM

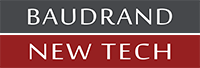

These machines allow the production of mesh panels or fences in rolls, with equal or different pitches.

Machines feed and straighten wire directly from coil, as well for longitudinal and crosswires.

A wide variety of accessories is available for the manufacture of specific products, to avoid costly secondary operations:

- Bending of V-shaped re-enforced meshes

- Bending of cable trays

- Corrugation of “Zigzag” separators

- Fabrication of spacers

- Re-cutting of panel ends

The production changeover time has been very carefully reduced to a minimum, thanks to the use of innovative, efficient and easy to implement mechanical devices.

Technical characteristics

| Characteristics | SM-1200 T/5-100 |

SM-1800 T/5-100 |

SM-2500 T/5-100 |

SM-2500 T/10-100 |

| Maximum panel dimensions | 1200 x 3000 | 1800 x 3000 | 2500 x 4000 | 2500 x 4000 |

| Max. nb. of longitudinal wires | 20 | 20 | 20 | 40 |

| Minimum pitch for longitudinal wires | 25 | 25 | 50 | 50 |

| Max. number of crosswires | ∞ | ∞ | ∞ | ∞ |

| Minimum pitch for crosswires | 12 | 12 | 12 | 12 |

| Wire diameters | 1,5 – 5,0 | 1,5 – 5,0 | 2,0 – 8,0 | 2,0 – 8,0 |

| Nb. of transformers | 5 | 5 | 5 | 10 |

| Each transformer’s power (kVA) | 100 | 100 | 100 | 100 |

| Options | ||||

| Mesh stacker | ✓ | ✓ | ✓ | ✓ |

| Mesh fliper | ✓ | ✓ | ✓ | ✓ |

| Bending for cable trays | ✓ | ✓ | – | – |

| Bending for panel fences | – | – | ✓ | ✓ |

| Welding of tubes on mobile fences | – | – | ✓ | ✓ |

Videos

Pictures

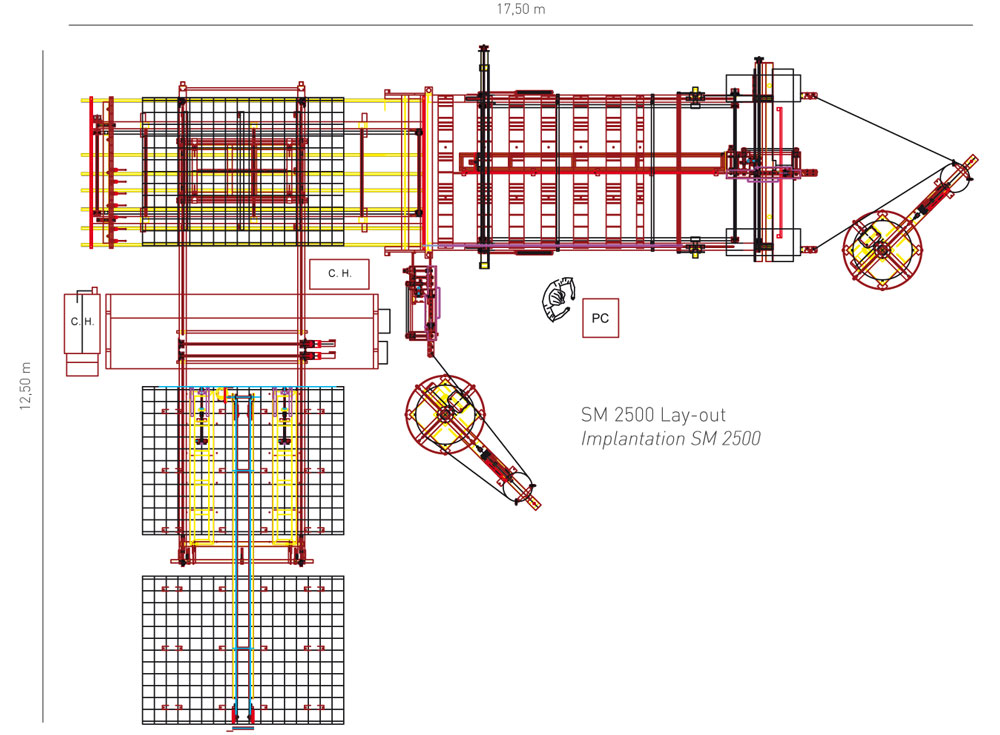

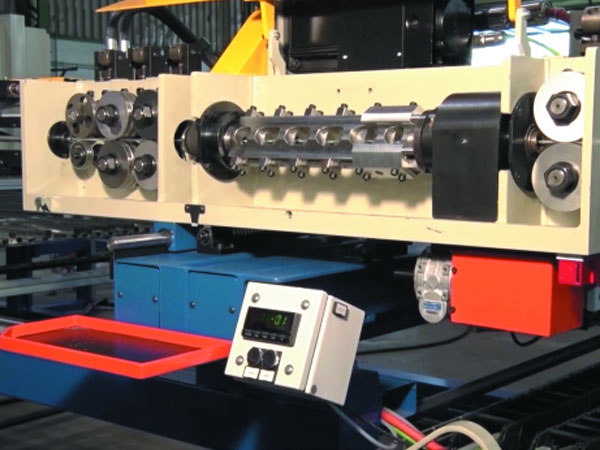

Wire straightener

Motorized setting of straightening fingers

Exit of panels

Sample of product, finished on the machine