Straightening-and-Cutting Machines

WSC

The straightening process can be followed by various second operation: deburring, chamfering, flattening, drilling…

The rotary straightener is set by means of an electrical command, which directly controls the positioning of straightening fingers. Thus, the setup is very quick and does not require any particular training.

Straightening setting parameters are saved in the program and will be instantaneously applied to any subsequent production processes.

The specific cutting system, patented by Buch, is extremely fast, and may be executed burr-free.

While the standard cutting angle is 90o, other values can also be achieved upon request, possibly with different cutting angles at the front and at the back.

Technical characteristics

| SMOOTH WIRES | CORRUGATED WIRES | |||||

| WSC-L4 | WSC-L7 | WSC-L12 | WSC-C12 | WSC-C16 | ||

| Wire diameters (mm) | Rm ≤ 800 daN/mm² | 1-4 | 2-7 | 4-12 | 4-12 | 6-16 |

| Rm ≤ 1 200 daN/mm² | 1-3 | 2-6 | 4-10 | 4-10 | 6-14 | |

| Rm ≤ 1 600 daN/mm² | 1-2 | 2-5 | 4-8 | 4-8 | 6-12 | |

| Rotary straightener | Manual adjust. | At the choice of the customer | Hyperbolic | |||

| Electronic adjust. | At the choice of the customer | – | ||||

| Speed (m/min) | Manual adjust. | 10-120 | 10-120 | 10-120 | 10-80 | 10-80 |

| Electronic adjust. | 10-100 | 10-100 | – | |||

| Types of cuts | Fixed | At the choice of the customer | – | |||

| Tilting | At the choice of the customer | – | ||||

| Floating | At the choice of the customer | |||||

| Number of cuts per minute | ≤ 150 | ≤ 150 | ≤ 150 | ≤ 100 | ≤ 100 | |

| Minimum cut-to-lenght (mm) | 50 | 50 | 50 | 500 | 500 | |

| Maximum cut-to-length (mm) | 3 000 | 3 000 | 3 000 | 6 000 | 6 000 | |

| Bars’ length tolerance (mm) | ± 0,2 | ± 0,2 | ± 0,2 | ± 5 | ± 5 | |

| Power (hp) | Depending on cutting and straightener | 30 | 40 | |||

Other configurations are available

Pictures

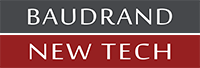

Rotary straightener

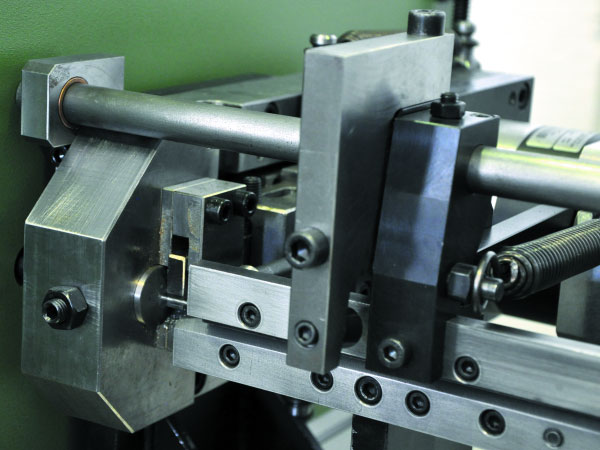

Fast cut-off system

Electric set-up of straightening fingers – to be memorized